Quick Details

1. High precision:

The laser beam has a small diameter and stable optical path, and its cutting accuracy can reach about 0.1mm.

The laser beam has high energy density, which can achieve precise cutting of thin plates. The kerf width is narrow, and the cutting surface is smooth without burrs.

The cutting process has minimal thermal impact on the material, reducing deformation and performance changes.

Servo motors, reducers, and dual drive gear rack transmission structures are sourced from famous industry brands.

|  |  |  |

| Servo Motors | Reducers | Laser Cutting Head

| Drive Transmission |

2. Good stability:

Fiber lasers have a long service life and excellent stability, ensuring stable and reliable cutting quality.

chillers, air compressors, machine tools, lasers, etc. are all connected to voltage regulators to ensure voltage stability during operation.

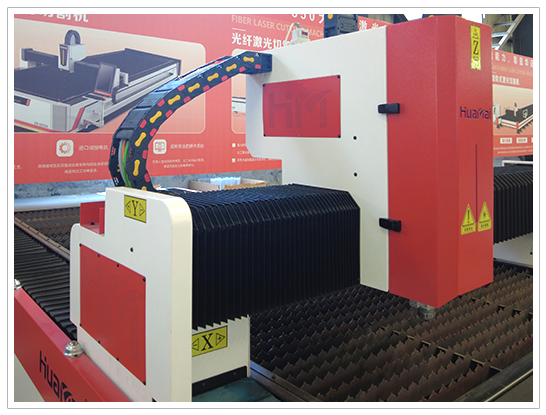

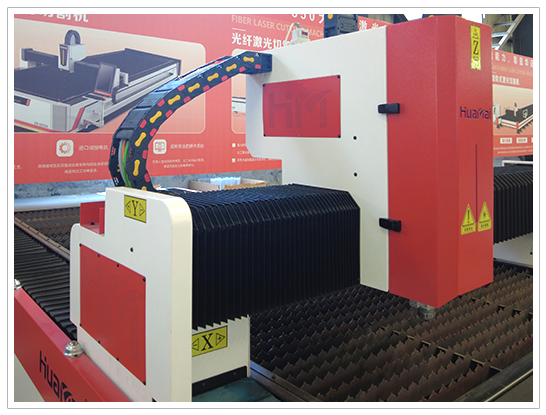

Adopting a gantry crossbeam design, high-strength aerospace grade integrated cast aluminum alloy, 4300 tons of pressure extrusion molding, and a hardness of T6 after aging treatment; Light weight, good rigidity, excellent dynamic performance, and smooth operation, combined with excellent heat treatment and machining processes, ensure the rigidity and long-term stability of the entire machine.

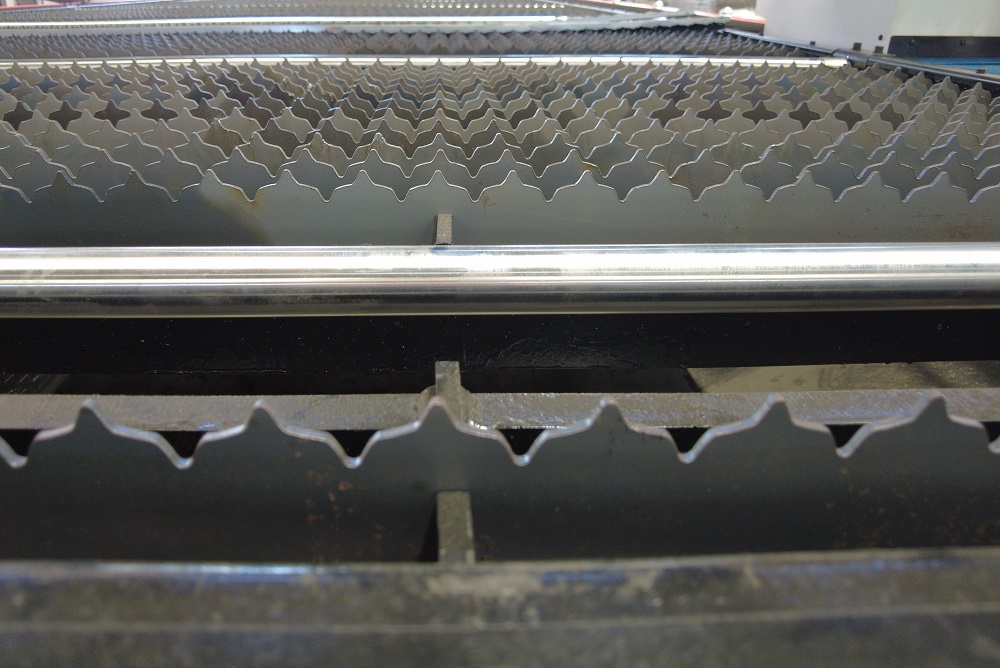

Adopting a fully enclosed dust-proof structure greatly improves the service life of the gears, racks, and linear guides installed inside.6mm serrated, paired with fireproof bricks for insulation, ensuring that the bed body will not deform during long-term use; 4 sets of drag chain support frames, with a total length of 6m. As the drag chain travels, it will not sag or break after long-term use.

|  |  |  |

| Chillers | Air Compressors | Lasers

| Aluminum Alloy Gantry Beam |

3. Safety braking:

Equipped with safety light barriers, when personnel accidentally enter the processing area, the equipment will immediately brake urgently, effectively avoiding dangerous situations. And equipped with intelligent collision avoidance and automatic edge finding functions to ensure the health of operators and stable operation of equipment.

|  |  |  |

| Safety Light Barriers | Nesting Software | Segmented Body

| Firebricks |

4. Intelligence:

Adopting professional and advanced 3D nesting software and CNC cutting software, with high-speed data processing and real-time control functions, it can automatically identify the characteristics of different tube sheet materials and optimize the cutting path. It supports multiple file format imports, and the operating system is compatible with various drawing, output, and management software. It can freely design various graphics or text, with flexible processing and simple and convenient operation;

Equipped with visual collision protection, seamless perforation, automatic obstacle avoidance, visual residual material cutting, flight cutting and other functions.

Application

Industrials: Aerospace, shipbuilding industry, rail transportation, automobile manufacturing, tram and motorcycle parts, petrochemicals, power energy, elevator manufacturing, pressure vessel manufacturing, pipeline engineering, sports and fitness equipment, medical equipment, engineering machinery, mining machinery, agricultural and forestry machinery, food machinery, lighting industry, telecommunications industry, textile machinery, environmental protection equipment, refrigeration equipment, steel structure, furniture and school tool manufacturing, kitchenware processing, bathroom hardware, electronic and electrical processing, electrical manufacturing, instrumentation, advertising production and decoration, building decoration, craft decorations, lamp decoration manufacturing, cabinet manufacturing, mold manufacturing, sheet metal processing, precision parts, laser external processing services and other mechanical manufacturing and processing industries.

|  |  |  |  |

Aerospace

| Shipbuilding | Train & Metro | Automobile | Motorcycle

|

|  |  |  |  |

| Elevator | Pipeline

| Furniture

| Electronic

| Lighting

|

Materials: Carbon steel, manganese steel, silicon steel, spring steel, stainless steel (SS), alloy steel, iron, copper (brass, purple copper), copper alloy, aluminum, aluminum alloy, gold, silver, titanium, titanium alloy, nickel, nickel alloy, chromium, chromium alloy, cobalt, cobalt alloy, galvanized sheet, aluminum zinc plated sheet, pickled sheet, electrolytic sheet, etc

Workpieces: Various types of metal pipes, including circular pipes, square pipes, elliptical pipes, rectangular pipes, channel steel, angle steel, C-shaped steel, T-shaped steel, I-shaped steel pipes, etc; Aircraft engine components, aircraft frames, helicopter main rotors, etc; Car body, doors, chassis components, roof windows and other parts; Ship plates, structural components, etc; Body structural components, chassis components, etc. of rail vehicles; Metal casings and internal structural components of electronic products such as mobile phones and computers; Steel beams and columns of steel structures; Office and household metal furniture components; Billboards, signs, decorations, etc; The framework of the stove, the shell of the range hood, stainless steel sink, cabinet panels and other kitchen and bathroom product components; Metal characters, signs, shop lightbox frames, etc;

|  |  |  |  |

Circular Pipes

| C-shaped Steel | T-shaped Steel | Stainless Steel Sink | Steel Structure |

|  |  |  |  |

| Square Pipes | Channel Steel | Kitchen Ventilator Case

| Plane Frame

| Phone Internal Part

|

Setup

PRE SALES SERVICE

Based on user needs, provide practical technical advice and corresponding product information from the user's perspective to answer and solve various questions raised by users. From a technical feasibility perspective, assist users in developing processing plans, provide processing equipment for on-site visits and inspections, sampling and testing, etc.

IN SALES SERVICE

Provide users with a complete set of product operation manuals for their processing sites, conduct on-site inspections, assist users in planning and designing production sites, as well as equipping water, electricity, and gas according to the actual situation on site, and provide technical training for user operators.

AFTER SALES SERVICE

The equipment arrives at the user's installation and commissioning site, and further training is provided to the user's operators, which is synchronized with installation and commissioning to ensure that the operators are proficient in the equipment operating procedures and fully put into production. Our company will send engineering and technical personnel to the user site irregularly every year for technical patrols, routine maintenance and inspection of equipment, answering technical questions raised by users, and providing upgrade training for user operators.

Laser Cutter

Laser Cutter